RUBBER

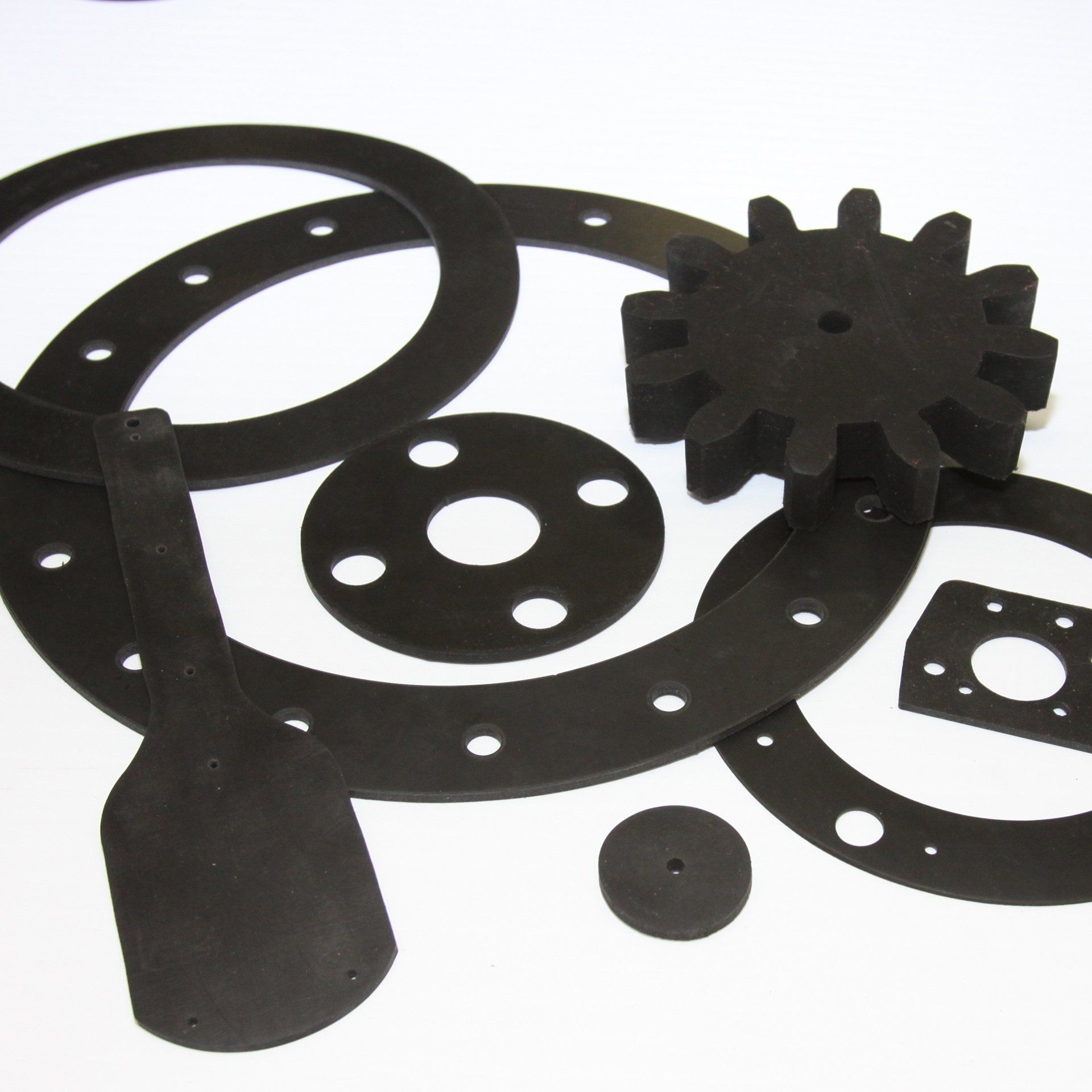

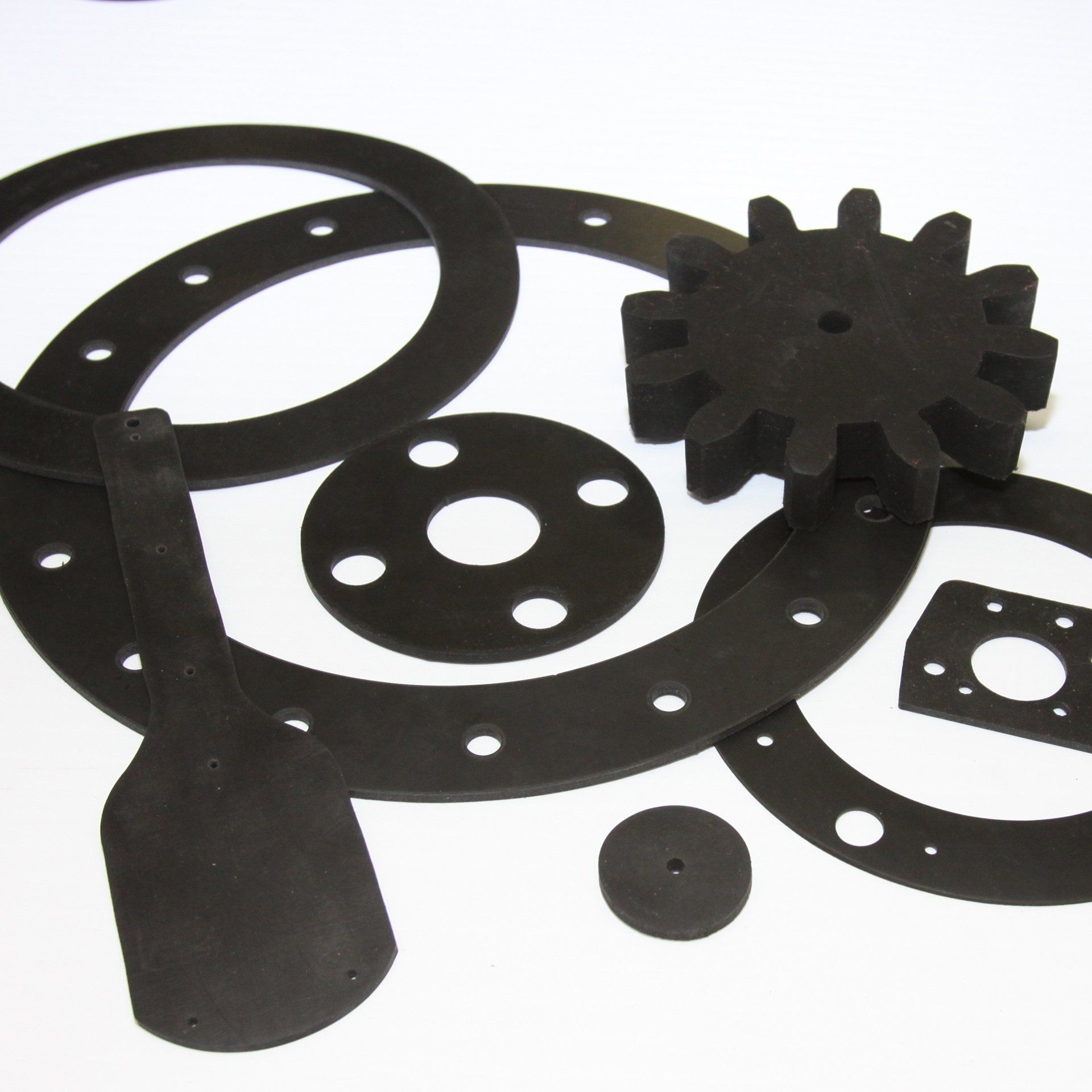

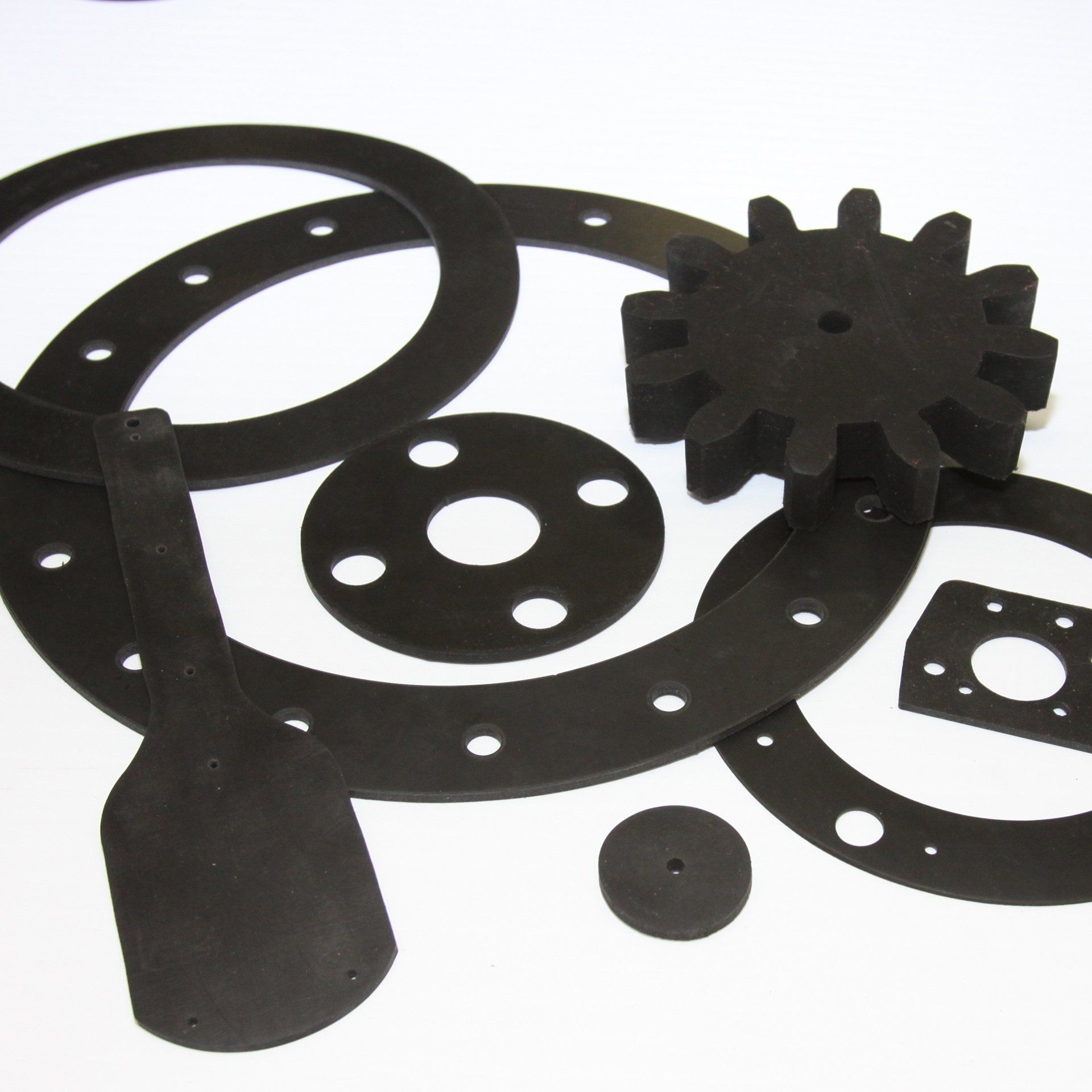

Rubber Gaskets

Commercial Gasket & Packing

recognizes the importance of material selection for manufacturing processes; die cutting, water jet cutting. We guarantee that we will produce the most appropriate rubber gasket to meet your unique application. Commercial Gasket & Packing provides customers with an extensive range of rubber elastomers to choose from. The most common types of rubber gaskets we supply are listed below. Our knowledgeable customer service team will gladly assist you in determining which material will perform best in your application.

Neoprene® Rubber EPDM Buna Nitrile

Neoprene® is the trade name for Chloroprene which was the first synthetic rubber. Neoprene rubber is an extremely versatile synthetic rubber used for harsh environment applications due to its moderate resistance to oil and petroleum base solvents. Neoprene exhibits good resistance to ozone, sunlight, aging, and other weather elements. Commercial Gasket & Packing fabricates die cut neoprene rubber gaskets and water jet cut neoprene gaskets in a wide variety of grades, thicknesses and hardness. Die cut neoprene gaskets are typically black in color and their hardness (durometer) spans from 30 to 90 durometer, Shore A. Neoprene gaskets are available with or without pressure sensitive adhesive (PSA) backing. We typically stock neoprene rubber with thickness ranging from 1/64″ to 1″ thick.

Available Neoprene® Grades:

- Commercial Grade Neoprene

- Medium Grade Neoprene

- High Grade Neoprene

- FDA Neoprene

- PSA Ready Neoprene

- Neoprene Sponge

Silicone Rubber

Silicone rubber is a high-performance elastomer with exceptional high and low temperature properties. Silicone molded and die cut gaskets can withstand within a temperature range of -75° F to +500° F. The low temperature flexibility of silicone is unmatched by any other elastomer. Commercial Gasket fabricates die cut silicone gaskets and waterjet silicone gaskets in a wide variety of grades, thicknesses and hardness. Silicone rubbers hardness (durometer) typically spans from 30 to 80 durometer, Shore A. Silicone Rubber is available in a full spectrum of colors including red/orange, black, gray, blue, white, and translucent. Silicone rubber gaskets are available with or without acrylic or high temperature pressure sensitive adhesive (PSA) backing. We typically stock Silicone rubber with thickness ranging from 1/64″ to 3/8″ thick.

Available Silicone Rubber Grades:

- Commercial Grade Silicone

- Spec Grade Silicone

- FDA (Food Grade) Silicone

- Silicone Sponge

- Silicone Foam

- Fluorosilicone

- Conductive Silicone

- Fiberglass Reinforced Silicone

- Extreme High Tear Silicone

- Extreme High Temperature Silicone

- Fabric Finish Silicone

- Flame Retardant Silicone

Viton® Gasket (Viton® Seal)Fluorocarbon (FKM)

Fluorocarbon elastomer Viton® (a trade name of the DuPont™ Corporation) is a high performance rubber compound known for its outstanding resistance to high temperature and broad range of chemicals. Viton® rubber’s permeability and compression set are excellent. Viton® displays good resistance to oils and solvents, aggressive fuels, and concentrated acids. Commercial Gasket fabricates die cut Viton® rubber gaskets and water jet cut Viton® rubber gaskets in a wide variety of grades, thicknesses and hardness. Viton® rubbers hardness (durometer) typically spans from 55 to 90 durometer, Shore A. Die cut Viton® gaskets are generally black or brown in color. Viton® gaskets are available with or without pressure sensitive adhesive (PSA) backing. We typically stock Viton® with thickness ranging from 1/64″ to 5/8″ thick.

Available Viton® Grades:

- Viton® “A” (Commercial Grade, 66% Fluorine)

- Viton® “A” (Premium Grade, 66% Fluorine)

- Viton® “A” (FDA Grade, 66% Fluorine)

- Viton® “B” (Premium Grade, 68% Fluorine)

- Viton® “F” (Premium Grade, 70% Fluorine)

- Viton® Sponge

EPDM Gasket – Ethylene Propylene Diene Monomer

EPDM rubber is a copolymer of ethylene and propylene. EPDM rubber is one of the most popular, versatile materials available. EPDM is known for its excellent ozone, sunlight, and heat resistance and exceptionally good weather aging properties. Its distinctive ability to stabilize color and resist harsh weather conditions makes it and ideal choice for outdoor applications. Commercial Gasket fabricates die cut EPDM gaskets and waterjet cut EPDM gaskets in a wide variety of grades, thicknesses and hardness. EPDM is generally black in color with the exception of FDA Approved EPDM which is white. The hardness (durometer) of EPDM rubber typically spans from 40 to 80 durometer, Shore A. EPDM rubber is available with or without pressure sensitive adhesive (PSA) backing. We typically stock EPDM Rubber with thickness ranging from 1/32″ to 3/8″ thick.

Available EPDM Grades:

- Commercial (Economy) Grade EPDM

- High Grade (Premium) EPDM

- Peroxide Cure EPDM

- White FDA approved EPDM

- EPDM Sponge

Nitrile Gasket (Buna-N Gasket)Acrylonitrile Butadiene (NBR)

Nitrile rubber, also known as Buna-N, is the most widely used elastomer for seals and gaskets. Its properties provide superior resistance to petroleum-based fluids, hydraulic fluids, gasoline, alkalis and acids. Nitrile is the polymer of choice for applications requiring oil and solvent resistance. Commercial Gasket fabricates die cut nitrile gaskets and water jet cut nitrile gaskets in a wide variety of grades, thicknesses and hardness. Nitrile rubbers hardness (durometer) generally ranges from 30 to 90 durometer, Shore A. Die cut nitrile gaskets are black in color however our FDA (Food Grade) nitrile gaskets are also offered in white. Nitrile gaskets are available with or without pressure sensitive adhesive (PSA) backing. We typically stock Nitrile Rubber with thickness ranging from 1/32″ to 3/8″ thick.

Available Nitrile Grades:

- Commercial Grade Nitrile (Buna-N)

- Mid Grade Nitrile

- High Grade Premium Nitrile (Buna-N)

- FDA White Nitrile (Buna-N)

- Transformer Oil Nitrile (Buna-N)

- Bio-Diesel Nitrile (Buna-N)

- Nitrile (Buna-N) Sponge

SBR Gasket (Red Rubber Gasket)Styrene-Butadiene (SBR, Buna-S)

SBR rubber is a synthetic polymer, commonly known as “Red Rubber”. SBR is a copolymer of styrene and butadiene and has properties similar to Natural Rubber. SBR is highly resilient and commonly used because it is cost-efficient and has the ability to deform to uneven flange edges. SBR (red rubber) exhibits excellent impact-strength, high tensile strength, abrasion resistance, heat resistance, and sustains flexibility at lower temperatures. Commercial Gasket fabricates die cut SBR gaskets and water jet cut SBR gaskets in a wide variety of grades, thicknesses and hardness. SBR rubbers hardness (durometer) is typically 75A durometer however our commercial grade ranges from 40 to 80 durometer, Shore A. Die cut SBR gaskets are generally red or black in color. SBR (Red Rubber) gaskets are available with or without pressure sensitive adhesive (PSA) backing. We typically stock SBR Rubber with thickness ranging from 1/32″ to 1/4″ thick.

Available SBR Grades:

- Commercial Grade SBR

- Premium Grade SBR

- Specification Grade SBR (Red or Black)

- Nylon Inserted SBR

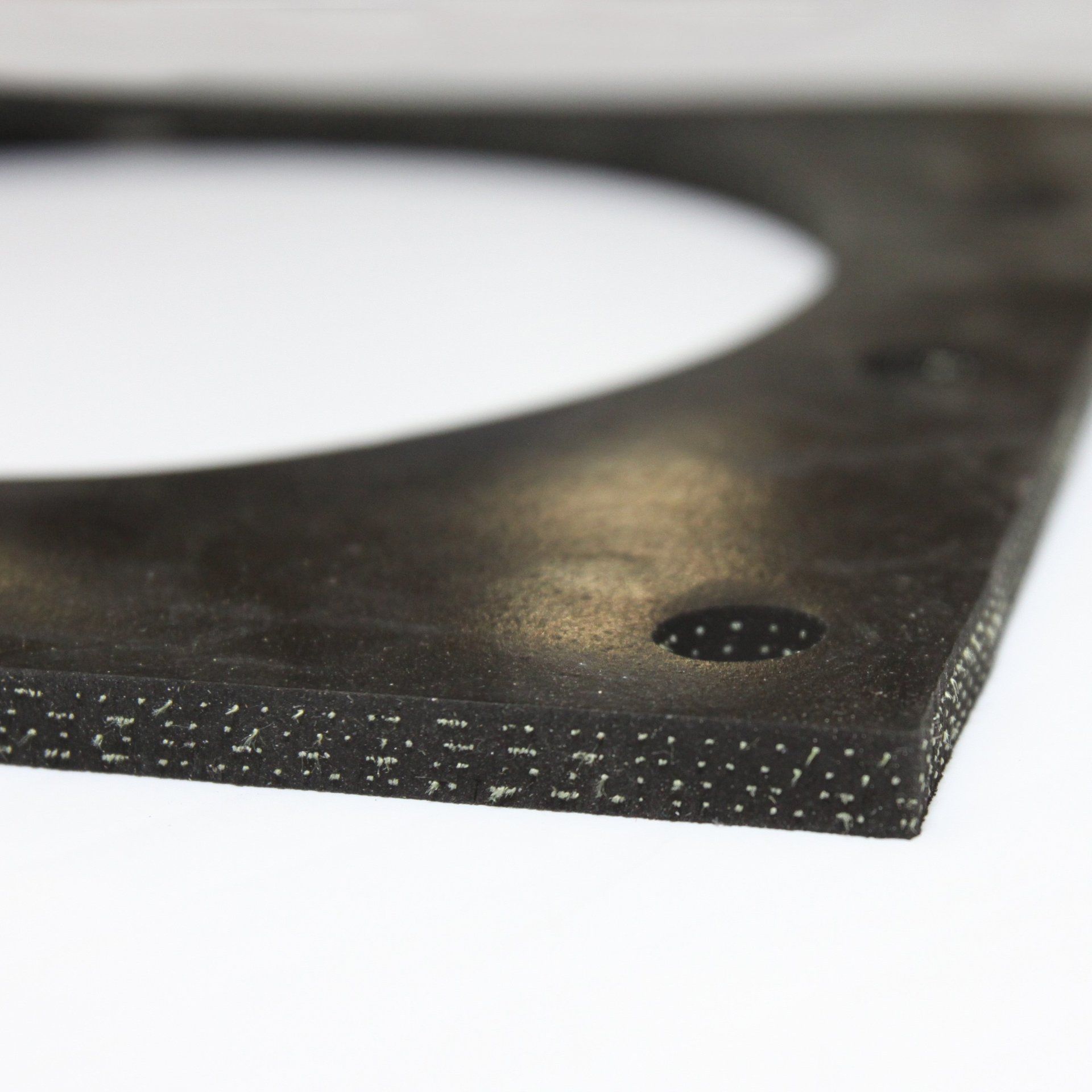

Cloth-Inserted (CI) Rubber Gasket

Cloth-inserted Rubber (SBR, Neoprene, EPDM, Buna-N) is a rubber sheet with a polyester, nylon, cotton, or fiberglass fabric impregnated in the rubber. Cloth reinforcement improves dimensional stability in flanged gasket applications with high compression loads. The fabric helps to reduce tearing when fastened. The materials construction typically includes one ply of fabric for each 1/16″ thickness. We typically stock CI Rubber with thickness ranging from 1/16″ to 3/8″ thick.

Butyl Gasket (Butyl Seal) Isobutylene-Isoprene Rubber (IIR)

Butyl rubber

is a copolymer of isobutylene and isoprene. Butyl rubber has exceptionally low gas, air, and moisture permeability. It offers excellent weathering properties and has outstanding resistance to sunlight, ozone, heat aging, oxygen, abrasion and tearing. Butyl is used in many applications requiring airtight rubber. Butyl rubber has excellent dielectric properties and is resistant to acids and alkalis. Commercial Gasket

fabricates die cut butyl gasketsand water jet cut butyl gaskets in a wide variety of grades, thicknesses and hardness. Die cut butyl gaskets are black in color and their hardness (durometer) spans from 40 to 70 durometer, Shore A. Butyl rubbers specifications are ASTM D 2000 – M1AA 407, 507, 607, 707. Butyl gaskets are available with or without pressure sensitive adhesive (PSA) backing. We typically stock Butyl Rubber with thickness ranging from 1/32″ to 3/8″ thick.

Natural Rubber Gaskets (Gum Rubber Gaskets)Polyisoprene (NR)

Natural (Gum) rubber

is an elastic material that was originally derived from milky sap or latex of some tropical plants (specifically the rubber tree). Natural rubber, also referred to as “gum rubber”, has many positive characteristics. It has superior resilience, high resistance to tear and abrasion, tensile strength, good compression set, and molding properties. Natural rubber is soft and displays good flexing qualities at low temperatures. Commercial Gasket

fabricates die cut natural (gum) rubber gaskets and water jet cut natural rubber gaskets in a wide variety of grades, thicknesses and hardness. The hardness (durometer) of natural rubber ranges from 40 to 60 durometer, Shore A. Die cut natural rubber gaskets are generally tan or black in color with the exception of our premium grade “red” gum natural rubber, which is used when an optimum combination of tear and abrasion resistance are required. Natural rubber gaskets are available with or without pressure sensitive adhesive (PSA) backing. We typically stock Gum Rubber with thickness ranging from 1/16″ to 3/8″ thick.

Available Natural Rubber Grades:

- Commercial Grade Natural Rubber (Color: Black)

- Premium Grade Gum Natural Rubber (Color: Red)

- Natural Rubber, Style 28* (Color: Light Tan)

- Pure Gum Floating Natural Rubber* (Color: Tan or Black)

- Non-Floating Gum Natural Rubber* (Color: Dark Tan)

- Protein Free (Synthetic Polyisoprene) Natural Rubber* (Color: Light Tan)

Polyurethane Gasket Polyester urethane / Polyetherurethane (AU/EU)

Polyurethane

is the toughest and most abrasion-resistant of all elastomeric materials. Polyurethane is a unique versatile material that provides the elasticity of rubber combined with the durability and strength of metal. Polyurethane consistently outperforms plastic, rubber and steel in its capacity to resist harsh environmental factors such as abrasion, heat, oil, acid, solvents and many chemicals. Commercial Gasket

fabricates die cut polyurethane gaskets and water jet cut polyurethane gaskets in a wide variety of thicknesses, colors and hardness. The standard thickness of polyurethane ranges from .005″ to 3/8″ thick. Polyurethane’s hardness typically spans frhttp://commercial-gasket.com/capabilities/die-cutting/om 60 to 90 durometer, Shore A. Die cut polyurethane gaskets are offered in standard colors of natural (amber) and black. We also provide custom thicknesses, colors, and durometers from 20A to 70D which are available upon request. Custom Gasket Mfg. offers FDA approved polyurethane gaskets for food applications. Polyurethane gaskets are available with or without pressure sensitive adhesive (PSA) backing.

Hypalon® Gasket Chlorosulfinated Polyethylene (CSM)

Hypalon®

is one of the most weather-resistant elastomers. It demonstrates almost complete resistance to UV/ozone and will not degrade with long-term sunlight exposure. It has excellent resistance to abrasion, oil, most chemicals and acids, it has good dielectric strength, and low moisture absorption. Its normal temperature range is between -50°F to 275°F. Hypalon® is ideal for the industrial, construction, automotive and petrochemical industries.

© 2017 Commercial Gasket & Packing / Designed and Hosted by

SalesPro Systems